The manufacturing industry is one of the most essential sectors of the global economy. It is estimated that the industry will be worth around $85.6 billion by 2024, with significant growth in sectors such as aerospace and defense, automotive, medical devices, and energy.

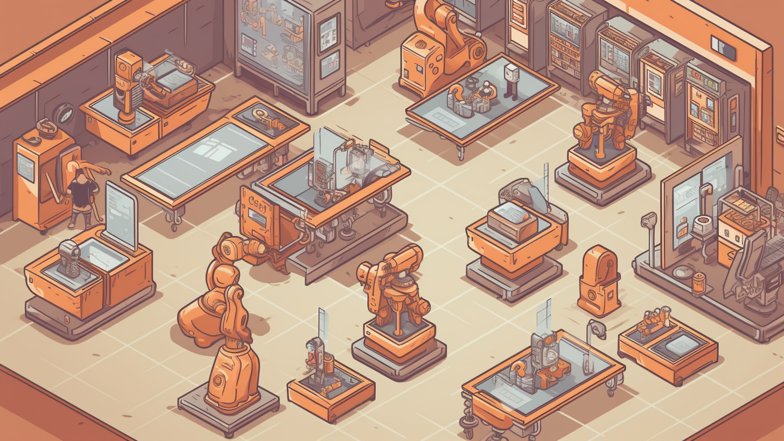

In recent years, the manufacturing sector has seen remarkable advances in technological innovations. From artificial intelligence to the internet of things, the sector has changed significantly. Among the latest technologies that are revolutionizing manufacturing is robotics. Robots are now being used in the manufacturing industry to execute various tasks that would otherwise be challenging or impossible for human workers.

One of the areas that robotics is significantly impacting in the manufacturing industry is the use of mobile robots. This article will explore how mobile robots are streamlining production processes in manufacturing.

What are Mobile Robots?

Mobile robots are machines that are designed to move, control, and navigate their environment automatically. These robots consist of a mechanical body, sensors that are used to identify their surroundings, and computer systems that are programmed to control their movement and actions.

Mobile robots are often used for applications that are difficult or dangerous for human workers. They can operate for prolonged periods and perform tasks with precision and efficiency.

Mobile robots can be configured in a wide range of configurations, including wheeled or tracked robots, autonomous drones, and unmanned ground vehicles (UGVs).

Mobile Robots Streamlining Production Processes

Mobile robots have become an indispensable part of the manufacturing industry. They are used to perform a wide range of tasks across the production value chain, including material handling, assembly, packaging, and inspection. Here are some of the ways that mobile robots are streamlining production processes in the manufacturing sector.

1. Enhancing Warehouse Management and Logistics

Mobile robots have been game-changers in the logistics and warehousing industry. They are being used for tasks such as material handling, order picking, and transportation. These robots can navigate complex warehouse layouts, terrain, and obstacles to perform tasks efficiently.

The robots have been programmed with algorithms that allow them to work collaboratively in the warehouse, reducing human errors, and increasing productivity. Mobile robots have also increased warehouse safety by reducing the number of people on the floor.

2. Increasing Safety on the Production Line

The manufacturing industry is one of the largest employers globally. However, the industry is associated with several safety hazards, such as machinery accidents and repetitive motion injuries.

Mobile robots are being used in the manufacturing industry to reduce human exposure to hazardous conditions. These robots can perform repetitive and dangerous tasks, allowing workers to focus on other critical activities in the factory.

The use of mobile robots has transformed the manufacturing sector by allowing humans to work in a safe and comfortable environment. Robots in the production line handle hazardous tasks such as dangerous materials, heavy lifting of products, and machine inspection, reducing the risk of injuries to human workers.

3. Improved Assembly Line Efficiency

The use of mobile robots has significantly improved the efficiency of assembly line tasks, reducing production time and costs. These robots can be fitted with sensitive torque sensors and cameras to ensure that assembly tasks are performed accurately and efficiently.

Mobile robots are also being used in the manufacturing industry to automate assembly lines, reducing the cost of production and increasing production speed. These robots can carry out repetitive assembly tasks, freeing human workers for more critical duties.

4. Optimizing Inspection Processes

The manufacturing industry requires strict quality control measures to ensure the production line's safety, quality, and accuracy. Inspection is a crucial production process that is essential in ensuring that production lines run smoothly.

Mobile robots are being used to perform quality inspection tasks in the manufacturing industry, improving production process efficiency. These robots can be fitted with cameras and sensors that can detect defects and faults, reducing human error rates.

The use of mobile robots in inspection processes has increased production uptime in the manufacturing industry by identifying defects earlier in the process, reducing costs associated with rework and wasted resources.

5. Flexibility in Manufacturing

The manufacturing sector is rapidly changing, with the need for quick and cost-effective production processes. Mobile robots have provided manufacturers with the flexibility to adapt to changing market demands and trends.

Mobile robots are agile and can adapt to different manufacturing conditions quickly. They can be programmed to work on different production lines, increasing their flexibility and reducing the time needed to set up and configure manufacturing processes.

The use of mobile robots in manufacturing enhances flexibility and improves production capacity quality and reduce costs. This allows manufacturers to remain competitive in an increasingly dynamic and competitive market.

Conclusion:

Mobile robots are changing the manufacturing industry by automating tasks that were previously difficult for human workers. The robots improve productivity, increase production capacity, reduce costs, and increase safety in the manufacturing process. The adoption of mobile robots in the manufacturing sector is a game-changer in the industry, revolutionizing traditional manufacturing processes. Mobile robots will continue to shape and drive the manufacturing industry's future while unlocking the door to global economic growth and prosperity.

Comments

Post a Comment